1. Move the probe left and lower it enough so it is away from the depo gun.

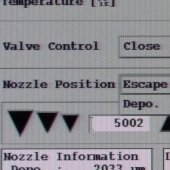

In the MANIPULATION CONTROLLER, turn off HOLD OFF and BUZ ON. Press ESC to remove the probe. Turn the beam OFF.

3. Close the S.C. AIRLOCK VALVE. Insert the specimen by turning a few degrees counterclockwise and releasing. Open the S.C. AIRLOCK VALVE.

4. Return to the area to be lifted out.

7. Press Continuous Scan. Locate the area that needs to be lifted out and adjust the focus, brightness, and contrast. Register the settings.

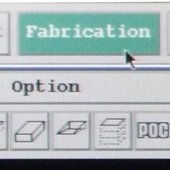

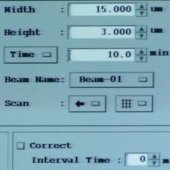

10. Use the DEPO TOOL to draw a rectangular box for the pad.

- Dimensions: 15 x 3

- Time: 10–12 min.

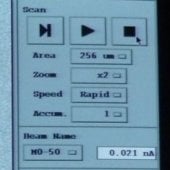

- Scan:

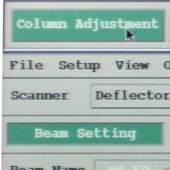

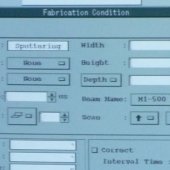

NOTE: Make sure the beam name is changed under the Fabrication Condition as well as on the right panel.