Spray and Combustion Laboratory

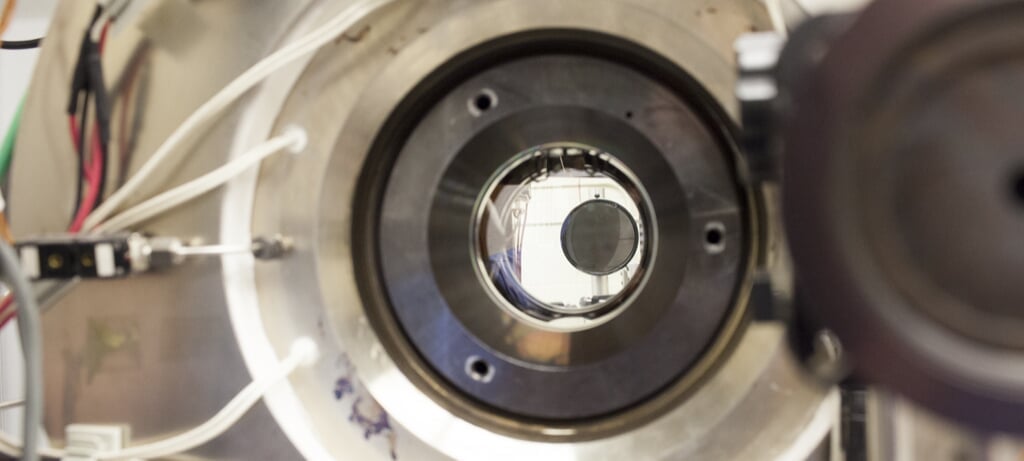

The central part of the laboratory is a high-pressure and temperature constant volume combustion vessel capable of replicating a wide range of engine in-cylinder conditions, including temperature, pressure, and composition. The vessel, a highly configurable chamber with interchangeable optical sapphire windows, features six primary ports including injector ports, ignition ports, and mixing fan ports, among others. There are an additional eight access ports for valves and instrumentation.

High-pressure fuel systems are available for:

- gasoline

- diesel

- alternative liquid fuels

- custom-mixture gaseous fuels

- natural gas

- syngas

- biogas

Studies are done using a wide array of optical and laser diagnostics. Applications include fundamental characterization of sprays and combustion as a function of advanced and novel ignition, injection, and combustion strategies, using conventional and alternative fuels to optimize spray and combustion processes while minimizing emissions and upholding efficiencies.

Climatic Control Chamber

The facility is a walk-in environmental chamber, seven feet by 10 feet by eight feet in dimension, for testing systems over a range of temperatures from negative 50 degrees Celsius to positive 50 degrees Celsius, with humidity control and heat rejection capability of 36,000 BTU per hour. It has exhaust and make-up air for use with fuel vapor and gaseous fuels, including hydrogen. The laboratory includes a pressure chamber with optical access for fuel, ignition, and injector studies. Applications include component testing, fuel cell stack-level sensing, and freeze/thaw studies.

Open End Shock Tube

The shock tube driver section is based on a Split‐Hopkinson pressure bar test air gun. The advantage of using a Split‐Hopkinson pressure bar test air gun as driver section is a fast-acting piston that replaces the diagram used in conventional shock tubes. This design of the shock tube allows for a quick reload and a safer operation. Currently, the shock tube is operated in an open‐end mode where spherical shock waves are generated at the end of the driven section.

Wind Tunnel

The wind tunnel has a test section of 12 by 12 by 24 inches, with an airspeed range of zero to 40 meters per second. The test section has customizable section panels. The capabilities are suitable for both research and educational use. Rapid prototyping technology allows for fabrication of complex, instrumented test models.