200. Large Rotary Style Subwoofer for Infrasonic Audio

The AES rotary subwoofer was designed and built as a high-output speaker capable of playing infrasonic frequencies (below human hearing) ranging from 1hz - 20hz. Frequencies in this range can be used as "practical effects" for theater and stage performances, with the project being able to resonate with objects in a room near their natural frequencies. The long wavelength of frequencies in the 1hz - 20hz range means that the produced sound propagates through solid matter with high efficiency. This creates an environment where you can feel the sound in your bones; the speaker's energy output can physically move objects in closed environments.

201. Cyber Range: Basic Cybersecurity Educational Modules

The goal of the Cyber Range is to create live demos to educate young learners about some of the possibilities in the world of cybersecurity. Our project was to take this environment and break down these possibilities into manageable chunks, allowing new learners to engage with and enjoy the Cyber Range.

202. Superior Cyber Range Attack and Defense Surface

The goal of the Superior Cyber Range Attack and Defense Surface is to develop an accessible web-based virtual environment to educate its users on common cybersecurity practices and techniques. The Superior Cyber Range Attack and Defense Surface covers a large variety of important practices such as password cracking, man-in-the-middle attacks, and Nmap scanning through real-time examples with virtual machines. The team plans out these scenarios to be implemented into the cyberrange and configure virtual machines to successfully execute the desired environment to inform the users on how these practices work.

203. RFID Inventory Tracking

The goal of the RFID Inventory Tracking project is to develop an inventory management method for small businesses using RFID antennas and tags that link back to a database server. The project aims to prove that this RFID system can independently keep track of a business's inventory across multiple sites, e.g., a warehouse or physical store. The purpose of this project is to provide a cost-effective solution for small businesses to be able to manage their inventory and provide a decreased risk of having lost inventory

204. Test Automation - Implementing and Testing an Integrated Learning Vision System

The goal of the Test Automation - Implementing and Testing an Integrated Learning Vision System project is to develop a proof-of-concept modular software framework that incorporates computer vision and machine learning to provide vision detection capabilities to a Universal Robot (UR), allowing it to perform one mode of action independently. The main purpose of this software is to reduce the recalibration and reprogramming of the UR, currently required by a trained worker. Additionally, the development of the software framework must be built in a modular and scalable way to allow for different modes of action, robots, or vision systems to be applied to the software framework, in the future, to accommodate the changing needs of the sponsor.

205. A Novel Device to Study Cellular Alignment in Biomedical Devices

The goal of this project is to develop a novel device to culture cells on nanofiber scaffolds under various flow conditions, in order to study the substrate- and flow-dependence of cellular alignment. The device will enable research to better understand device-related thrombosis on Left Atrial Appendage Occlusion devices for atrial fibrillation treatment. Currently, the project team is modeling and manufacturing two devices for cell culture (one basic device and one device that mimics the left atrium), developing a procedure to culture cells under flow conditions, developing electronic systems and code to support flow monitoring, culturing multiple primary cell lines for testing, and collecting preliminary data for future studies

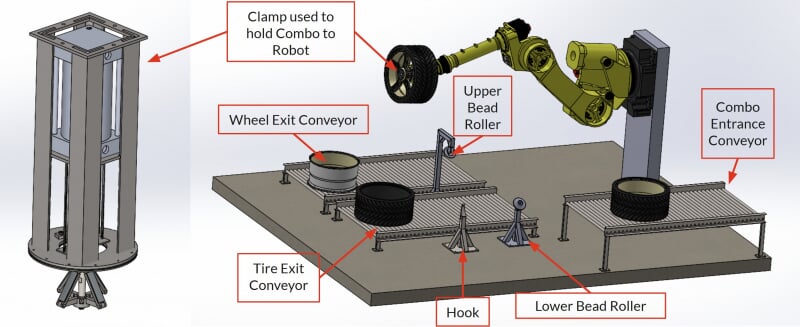

206. Automated Tire and Wheel Demounting System

The goal of the Automated Tire and Wheel Demounting System is to develop a tire demounting system that does not require an operator. Currently, the customer uses manual tire changing machines to demount faulty tire and wheel assemblies, which leads to quality issues and operator safety concerns. The main goal is to automate this process to relieve the issues which are currently seen by the customer, and decrease the time to demount a tire. The team is designing components that will be used by an industrial robot to autonomously demount a tire and wheel assembly.

207. Emergency Mesh Network

The Emergency Mesh Network is a network using drones and custom IOT devices implemented with the IEEE 802.11ah protocol to help send emergency messages when a network is down. The concept is to attach custom-built IOT devices that will include a Raspberry PI 4B with a Halow module to a drone and be able to deploy the drones in a grid formation to cover a large area to transmit and receive emergency messages. Our end goal is to have Halow modules on multiple drones to make up a mesh network that can be deployed anywhere. The drones could be deployed in natural disasters to help people communicate or in isolated areas to try and find someone.

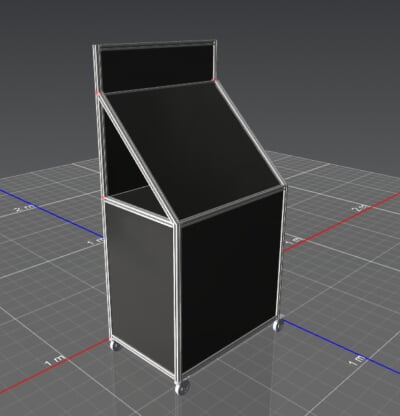

208. MTU Electrical & Computer Engineering Kiosk

The goal of the MTU Electrical & Computer Engineering Kiosk project is to create an informational and interactive kiosk for the ECE Department. The main purpose of this kiosk is to provide current and prospective students with more information about the department such as details about degree plans, enterprises, internships, and more. This project involves both hardware and software elements, including the construction of the physical kiosk and the informational website that will be displayed.

209. Clinical Blood Clot Testing Kit

The Clinical Blood Clot Testing Kit Project addresses gaps in understanding the mechanical properties of in-vivo blood clots. Sponsored by Boston Scientific, this senior design project aims to enhance clot removal device design by providing real-time, in-lab mechanical data. The kit will enable the immediate testing of clots extracted during thrombectomy procedures, supporting better simulations and device optimization. Project objectives include creating a compact, user-friendly, and reusable testing kit suitable for use in operating rooms. The primary focus is on compression testing and density measurements, chosen for their reliability, ease of use, and data relevance.

210. Vision System for Parts Assembly Process

The Vision System for Parts Assembly Process project aims to error-proof an existing manual assembly process by utilizing a vision system in tandem with AI technology. The purpose of implementing a vision system into this assembly process is to verify part presence, orientation, and location to decrease the amount of reworking on non-conforming parts and increase efficiency to meet daily quotas. This project is currently in its final phase. In this phase, the team created and conducted a validation test to ensure the selected system was the best fit. The team is also training the vision system and accompanying AI tools to learn part presence, orientation, and location.

211. ITC Capacitor Bank Protection Team

Implement resilient protection for a capacitor bank using real-time impedance measurements to address system and environmental changes using microprocessor relaying.

212. Crimmins Renewable Energy Distribution

The Crimmins Renewable Energy Distribution team is conducting a study to determine the feasibility of implementing a solar field at the previous Presque Isle Power Plant site. In collaboration with the Alternative Energy Enterprise, the team designed an array of solar panels and inverters and selected the necessary equipment for interconnection and protection of the existing substation. The team evaluated different design options with the chosen equipment, performed a financial analysis, and determined baseline costs and a potential payback period based on local power buyback programs.

213. Battery Indicator System for Stationary Power Storage System

Our task is to develop an at-a-glance status display for the end of a shipping container, providing a clear visual representation of the system's state. This display will consist of a grid of colored indicators, where each column represents a battery string, and each individual indicator corresponds to a battery module within that string.

The Aries Grid System has an existing controller that monitors system status. Our design must interface with this controller over MODBUS, ensuring real-time updates and accurate status representation. Additionally, we need to develop a dedicated controller to manage the display, process data from the Aries Grid system, and drive the indicator grid effectively.

Each column in the display will visually communicate the status of its respective battery string, using different color-coded indicators to reflect operational conditions, warnings, or faults. This intuitive approach will allow for quick diagnostics and streamlined maintenance, improving system oversight and efficiency.

214. Whirlpool Gasket Data Acquisition Fixture

In order to streamline Whirlpool Corporation’s research and development of sealing systems, a gasket testing fixture is necessary. Standardization of testing is paramount, so this permanent fixture is intended to gather statistically relevant information and ensure repeatability and precise data acquisition to determine optimal hinge placement and allow for more precise testing regarding the gasket and door assembly relative to the rest of a Whirlpool Refrigerator. The current design focus is primarily on integrating sensors and actuators upon the previously existing mechanical fixture to simulate the device’s functionality via Labview. A graphical user interface will enable precise control of the actuators and display real-time measurements of the laser distance sensors. Additionally, the data will be displayed graphically based on the sample gaskets provided by Whirlpool, making it easy for the operator to identify the optimal gasket within the testing parameters.

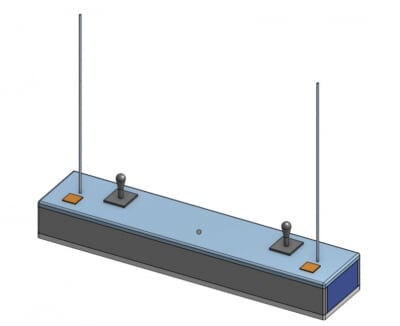

215. Symphonic Sonic Sandbox

The goal of the Sonic Symphonic Sandbox is to allow members of the MTU VPA department to have a modular control box to modify auditory waves in a sandbox environment. The control box will have a pair of at least three or more modules that can be used to alter waveforms for sound generation. These modules include but are not limited to joysticks, pressure pads, and theremin antennas. All of these audio modules will be connected via an Arduino microcontroller and will be connected to a PC via a MIDI to USB connection, where the VPA department has pre-existing software to support these modules. As of right now, our parts have been ordered, and a final design is currently being finalized, programming the Arduino is projected to start in the following days ahead.

216. LIDAR-based Ice Detection (LID)

The goal of the LIDAR-based Ice Detection project is to create a system utilizing LIDAR that will alert pilots to ice building on their plane's wings in real time. Currently, in aviatio,n the only way to detect icing is by having the pilot look at the wing, the project aims to remove human error. The team is developing ROS2 code that will translate LIDAR data, for distance and reflectivity, to tell if icing is present or not to accomplish this goal.

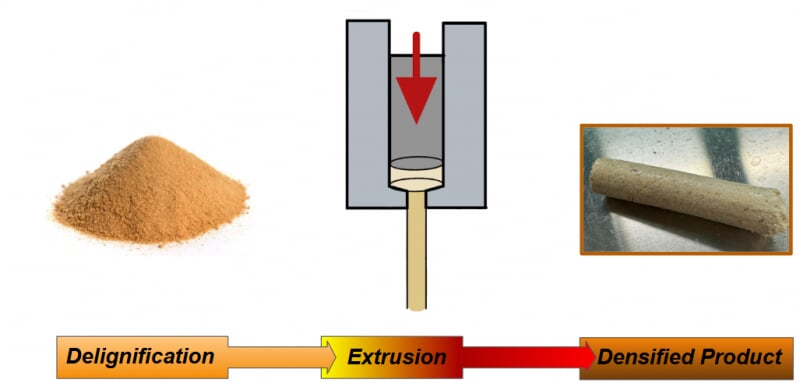

217. Waste Wood Upcycling for Defens

The goal of the Waste Wood Upcycling for Defense (WUD) initiative is to develop a scalable process for upcycling wood waste into densified wood products through the extrusion of delignified wood fibers. The project focuses on optimizing the material's physical properties by reducing lignin content, controlling moisture, and adjusting extrusion parameters. The team is investigating the impact of these factors on the strength, durability, and hardness of the densified wood. Through this process, the project aims to enhance fiber bonding, compaction, and microstructural integrity, with a focus on improving the material's mechanical properties.

218. SPO Green Sand Press

The goal of the SPO Green Sand Press project is to redesign and refurbish a sixty-year-old squeeze press to comply with OSHA safety standards and to simplify the pneumatic system used to operate the machine and safety controls. The main purpose of this redesign is to modify the squeeze press for staff and classroom use in the Material Science Department’s Foundry.

219. Improved Performance of Windows Build System

The project aims to address the inefficiencies in the current Windows build system caused by outdated components, including Perl scripts. These components have been in use since the early stages of the build system’s development, leading to bottlenecks that affect overall performance. By rewriting these components in Rust or C#, the project will reduce build times, enhance reliability, and future-proof the system.

220. Dynamic Monitoring for Tennis Injury Prevention and Awareness

The goal of the project is to develop a wireless, wearable device to monitor and assist in technique awareness and injury prevention of tennis players. The team has been working with the MTU tennis coaches and team members to better understand the needs and translate those needs into hardware and software that will benefit players at all levels and ages. The project will provide insights into player technique and trends that may lead to injury. Such a device is beneficial for preventing injury and pin-pointing injury-causing techniques that can assist sports trainers, coaches, and players.

221. Infusing Bath Additives for Wellness Applications

The bath additive market is highly competitive and saturated. To differentiate themselves from other competitors in the bathing market, Kohler is aiming to provide experiences that deliver real, quantifiable benefits. This team was tasked with the research and recommendation of particular bath additives to enhance muscle relaxation and improve skin quality. Additionally, the team was tasked with developing a delivery mechanism that would be compatible with the top-identified additives. The device needs to be able to deliver a controlled, repeatable dose to ensure an experience that will provide real benefits.

222. Consumers Energy Wildfire Mitigation

The goal of the wildfire mitigation project is to develop a wildfire mitigation plan for Consumers Energy in their distribution area in northern Lower Michigan. The main purpose of this plan is to find possible solutions for Consumers Energy to implement on their low-voltage distribution lines in Michigan to reduce the risk of their distribution lines starting a forest fire. Currently, the team has developed multiple potential solutions and is using a decision matrix to identify the best solutions to pursue.

223. Recycled Cast Aluminum Alloy Development

The goal of the recycled cast aluminum alloy development project is to take a category of aluminum scrap that is not seen as very valuable in the current market and improve the physical properties of the alloy in a way that gives it more value. Work has been done to determine types and quantities of primary-grade alloying elements to add to scrap compositions.

224. Cable Tensioning Device for Trauma and Reconstructive Surgeries

The goal of this project is to design a cable tensioning device for trauma and reconstructive surgeries. This device will allow the user to easily apply and maintain predictable tension on metal cables around bone to reduce fractures during surgeries. The project is currently in its second phase. In this phase, the team is prototyping a cable tensioning device with a removable handle, allowing the user to tension multiple cables, a common requirement in long-bone surgeries.

225. Real-Time Detection and Analysis of Snow Coverage atop Solar Panels

The goal of our project is to correlate and apply information gathered via machine learning (ML) model analysis of drone footage to physical locations in real-time. We use a model trained to identify snow-covered solar panels, which collects data about the snow coverage characteristics and passes this information -- along with location data -- to a database which is displayed via a GUI. This aggregated data is used to highlight regions of concern across a solar field to allow for effective and efficient deployment of clearing measures.

226. Development of qPCR Assay for Clinically Relevant Bacteria used in Chemical Disinfection Confirmation Testing

The project's goal is to develop a method to confirm chemical disinfection efficacy is faster than the current industry standard. The team has designed primers to specifically target clinically relevant bacteria for use in quantitative polymerase chain reaction (qPCR) analysis of soiled and disinfected samples. This project is currently testing developed primers for five bacteria species for reproducibility across trial runs and accuracy compared to the current industry standard, agar plate counting (APC). The future goals of this project will include trials to test whether each primer is specific to its intended bacteria species and can work in conjunction to properly enumerate each bacteria species in a homogenized sample with an unknown concentration.

227. Quantifying the Effects of Zinc on Ductile Iron's Microstructure and Mechanical Properties

This project seeks to quantify the effects of zinc on ductile cast iron's microstructure and therefore mechanical properties. This is a largely unknown and unexplored topic, but is gaining importance as industry considers adding galvanized, or zinc coated, scrap steel into charge material. The project evaluates a hypothesis exploring zinc's role as a ferrite promoter as suggested in the very limited literature on the subject, and incorporates zinc additions in castings used for microstructural analysis and tensile testing.

228. Simulation-Based Human Body Impedance Modeling for Realistic IEC Defibrillation Safety Standards

Our project aims to develop a human body impedance simulation model to accurately measure electric field strengths on the body’s surface during external defibrillation. This project addresses over-engineering in patient monitoring devices, which are required to withstand high-energy defibrillation pulses per IEC 60601-1:2005. Using Sim4Life simulation software, we model defibrillation pulse propagation throughout the human body to generate realistic data. These insights will help establish more practical immunity test limits for medical device-applied parts, reducing unnecessary costs while maintaining patient safety. Ultimately, our team seeks to streamline regulatory approval processes and contribute to the development of more efficient, cost-effective medical devices.

229. Prosthetic Compatibility Device

There is a strong need in the prosthetics industry for both a more accurate fitting method and long-term swelling/hypertrophy/atrophy trend data collection. As such, the prosthetic compatibility team seeks to develop an innovative, all-in-one pressure and topological characterization device(s) for below-the-knee amputees that can fill this need. The project is currently in proof-of-concept prototype testing, and after such testing will move forward with application-based design engineering.

230. Simulation and Analysis of Voltage Drop, Thermal Shock, and Humidity Cycling on a Wire Harness

The goal of this project is to use the previously developed finite element analysis (FEA) model for terminal-wire crimps to perform virtual simulations. The simulations correspond to all stated processes from the USCAR-21 standard. The team will also try to correlate the model with the actual physical testing data on the following:

- Initial resistance/voltage drop simulation

- Thermal shock simulation

- Resistance/voltage drop simulation after thermal Shock

- Humidity cycling simulation

- Resistance/voltage drop simulation after humidity cycling

231. Developing Infrared/Visible Light Therapies for the Bathroom

This project aims to integrate light therapy into wet environments, such as showers and bathing spaces, while maintaining proven effectiveness. Given the growing popularity of light therapy in these spaces, many products claim benefits without scientific backing. Using MCML software, the team developed a code for a Monte Carlo multilayer simulation that simulates light propagation through skin. This simulation provides a tool for Kohler to understand how different wavelengths and light doses affect the skin.

232. The Effect of Cerium on Sensitization and Weld Strength of 5xxx Series Aluminum Alloys

5xxx series aluminum alloys are widely used in the welding industry due to their excellent combination of weldability and strength. However, these alloys are susceptible to sensitization, an undesirable aging process where magnesium segregation at grain boundaries leads to intergranular corrosion. This project investigates the effect of cerium addition on both sensitization resistance and strength in welded 5xxx aluminum alloys. Cerium is expected to interrupt the ꞵ-phase (Mg2Al3) continuity along grain boundaries, thereby blocking corrosion pathways. Mechanical properties and sensitization resistance will be evaluated through specimens produced via a TIG-based wire arc additive manufacturing (WAAM) process.

233. Data Center Hot Aisle Isolation

The goal of our project was to help lower the temperature inside Server Room 328A, which has always been notoriously hot, even without any students present. When a full class is in session, the room quickly becomes unbearable. Our project aims to monitor various locations within the server room and then construct a false wall to better direct the flow of hot air toward the exhaust.

234. MTU Foundry Extrusion Press Quench Box

The goal of the MTU Foundry Extrusion Press Quench Box Project is to provide the MTU Foundry staff with a sustainable and professionally designed quenching system. This quench system will be used with the extrusion press. Additionally, this project will repair and validate the butt shear to allow for easier removal of the puck after the extrusion is complete.

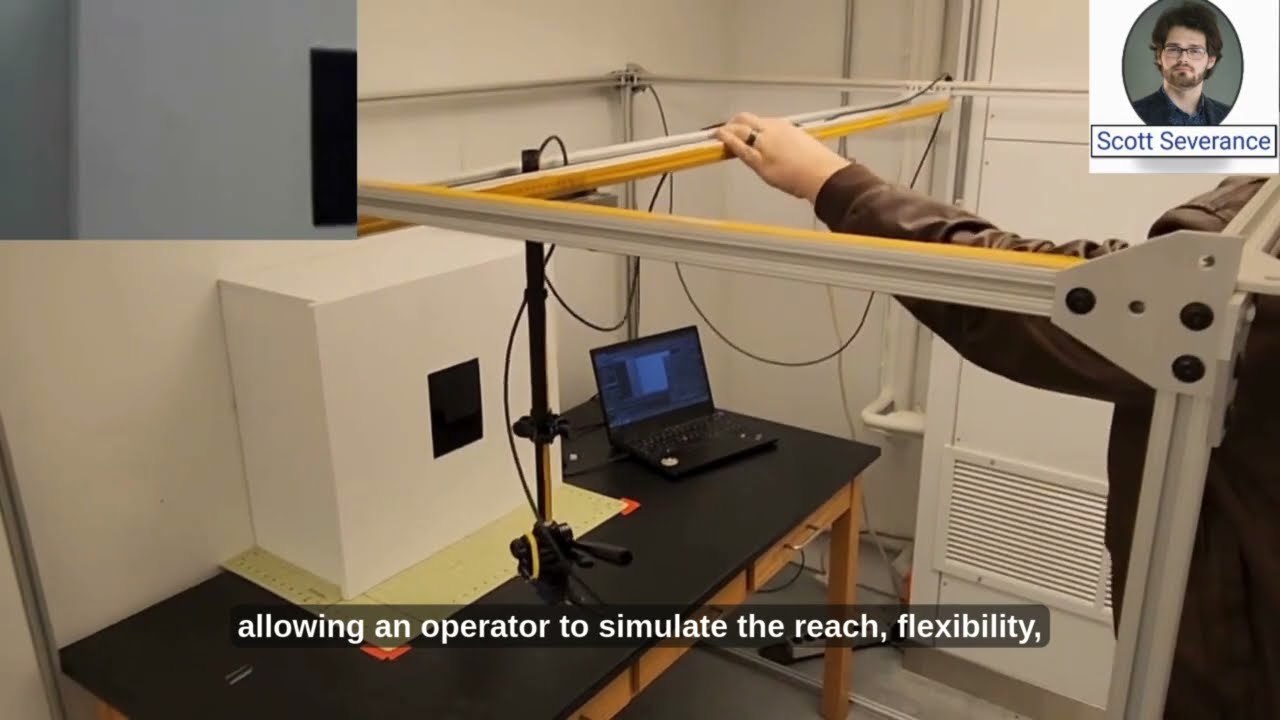

235. Moonstep: Hypo-Gravity Simulator for Lunar Locomotion Modeling

The goal of the hypo-gravity simulator is to research the metabolic costs of different lunar gait patterns. Moonstep approaches this goal by utilizing a combination of elastics that can provide upward force corresponding to 5/6 of an individual's weight. Participants can range from 100 to 200 lbs and measure 5' to 6'4''. This design distinguishes itself from other concepts as it can accommodate gait patterns with significant vertical displacement. The configuration of the elastics ensures a more precise and consistent force within the operating gait range, another area of improvement compared to other designs.