300. Portable Oxygen Concentrator

The goal of the Portable Oxygen Concentrator (POC) project is to develop a device with industry-leading oxygen purification capability. This project was started by a leading producer of oxygen therapy devices, Advanced Interactive Response Systems (AIRS), and is focused on an oxygen purification system that is highly efficient and achieves 99% oxygen purity. POC has been associated with the Consumer Products Manufacturing enterprise since 2024, and is in the beginning stages of research and development.

301. Biogas Anaerobic Digestion

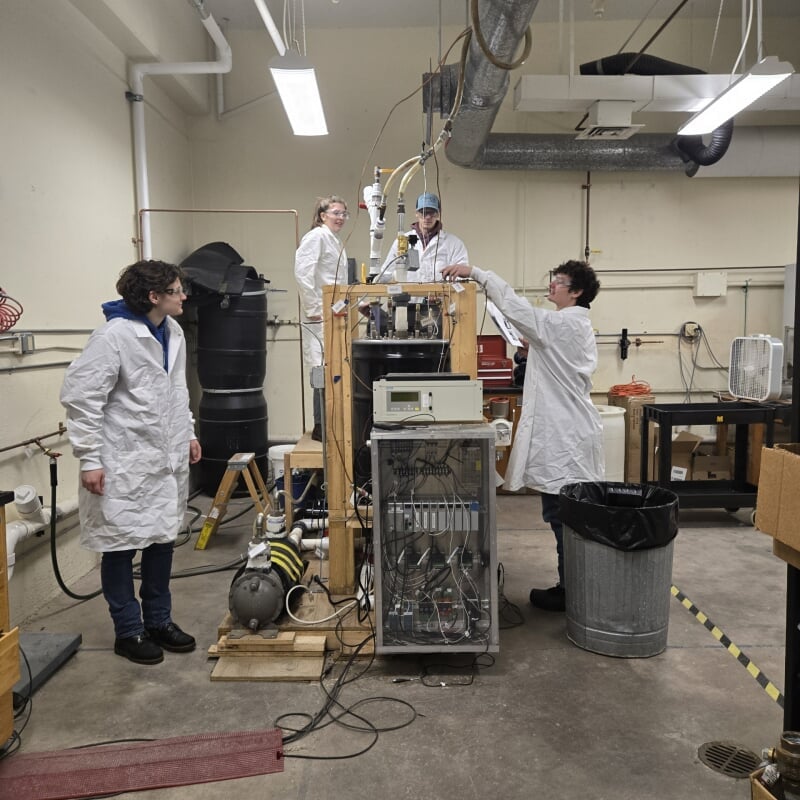

The goal of the Biogas Anaerobic Digestion project is to anaerobically digest university food wastes to produce methane gas. The Biogas team is focused on constructing a small-scale pilot plant to evaluate the feasibility, benefits, and requirements of a full-scale anaerobic digester on campus. Biogas has been associated with the Consumer Products Manufacturing enterprise since 2018 and is preparing to conduct a full trial of the pilot plant. They are simultaneously creating a small-scale model of the pilot plant.

302. Accessible, Affordable, Authentic (AAA) Prosthesis Project

The AAA Prosthetics team, an MTU healthcare research team, is focused on developing a below-the-knee foot and ankle prosthetic. This product will be marketed for low-income or third-world countries, and it will be lightweight, with low cost and easy maintenance. AAA Prosthetics has been an active project associated with the Consumer Products Manufacturing Enterprise since 2017 and is currently finalizing a prototype.

303. Cast In Steel: George Washington's Broadsword

This project is to design a replica of one of George Washington's historic swords. This project aims to recreate a modified version of his Alte Presentation Broadsword. The project encapsulates the designing of the sword, simulating the casting process, casting a replica sword, heat treatment and finishing, before being tested at the competition.

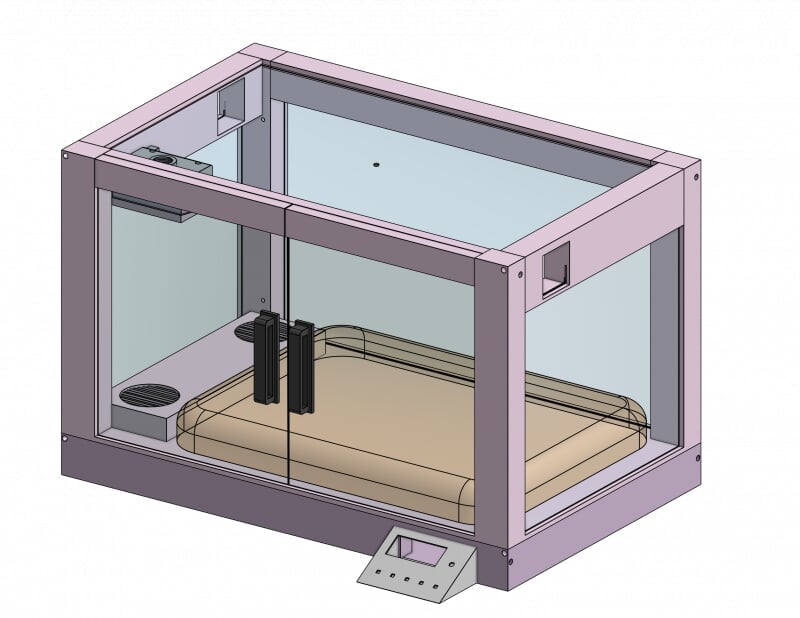

304. Innovative Global Solutions - Infant Incubator

The goal of the IGS enterprise's Infant Incubator project was to solve an identified problem of high mortality rates in remote and economically disadvantaged regions in Sub-Saharan Africa. The team intends to alleviate the existing gap in care by developing a low-cost low-power infant incubator solution. The project is currently in development of a 4th prototype that integrates standards, a unified controls system, an infant attachment for recording vitals, and a custom humidifier and control circuit for it.

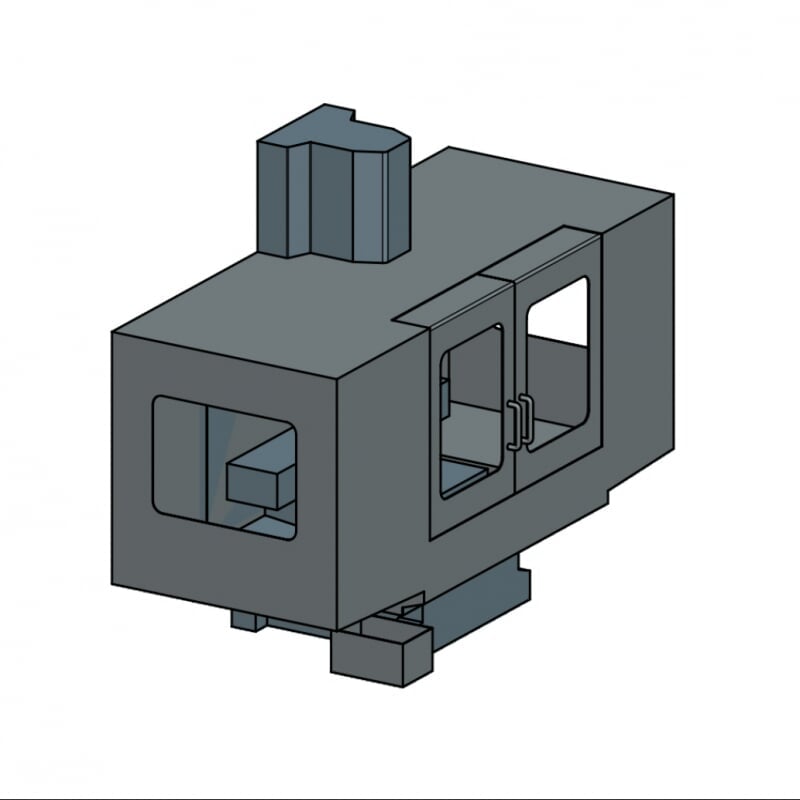

305. Manufacturing and Mechanical Engineering Technology CNC Mill Enclosure

The objective of this project is to design and build an enclosure for the MMET department’s donated 2006 HAAS TM2 CNC mill. They want the enclosure to contain both chips and cooling fluid, as well as broken tools, dislodged parts, and pinch points. The enclosure will also need to have a safety interlock system within its doors to act as a safety switch and replace the one currently on the machine. There is also a request to increase the accessibility of the machine if possible and reduce cleaning/maintenance times.

306. Price Prediction of RAM Prices

The Price Prediction Team at ITOxygen Enterprise are working on an algorithm that can determine whether buying RAM chips at spot market price or through a contract would be more viable for a customer. This uses data from 2017-2020 collected by the previous team and aims to make an algorithm that predicts the price based on many different factors including, stock prices, GDP, unemployment rates, imports, exports, and more. As the project moves forward the team is getting closer and closer to implementing a machine learning algorithm that accounts for outliers and non linear relations. This algorithm will be trained and tested on the previously mentioned data until they get a desired result.

307. Campus Rain Gardens

Michigan Tech’s campus has several problem areas where excess water accumulates from precipitation and snow-melting events. In some circumstances, such locations impact the ability of students and faculty to navigate campus comfortably and safely, especially in highly trafficked areas. Green Campus Enterprise’s Bioretention Team is working to design bioretention systems, specifically rain gardens, to be implemented with the intent of reducing water accumulation on campus, creating a designated space for increased biodiversity on campus and naturally filtering pollutants in the stormwater before it reaches the Portage.

308. Clean Diesel

The goal of the Clean Diesel project is to convert university dining hall waste oil into biodiesel fuel. The Clean Diesel team is focused on improving MTU’s public image through its pursuit of sustainability; this project refines waste dining hall cooking oil to create clean biodiesel that can be used by campus and local farmers. Clean Diesel has been associated with the Consumer Products Manufacturing enterprise since 2020 and is continuing to test the manufactured biodiesel in an engine and attempting to manufacture a machine that will produce biodiesel.

309. Installation of Solar Panels at the EERC

To reduce Michigan Tech’s carbon footprint, Green Campus Enterprise is exploring renewable energy solutions on campus. MTU Facilities staff has identified a potential project to install solar panels on the EERC building. The EERC Solar Team is conducting a feasibility study, including a site assessment, system sizing, energy storage, and cost analysis, to determine if this project is practical and beneficial. The installation of solar panels will help lower energy costs and support Michigan Tech’s sustainability goals.

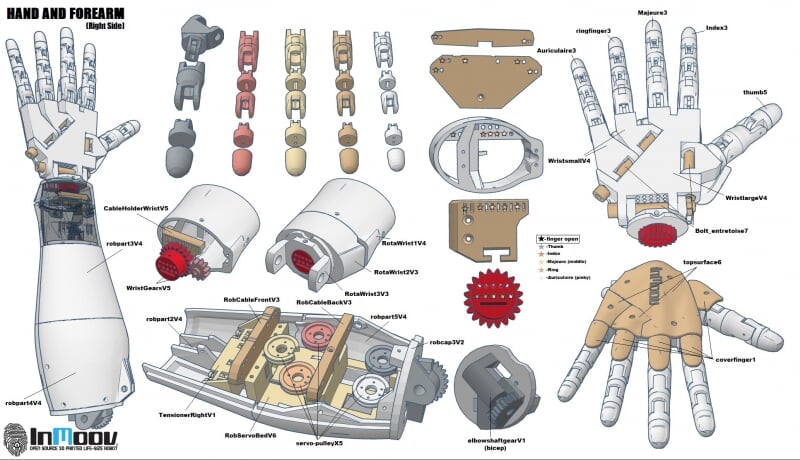

310. Mobile, Affordable, Responsive, and Comfortable (MARC) Prosthetic Arm

The goal of the Mobile, Affordable, Responsive, and Comfortable (MARC) Prosthetic Arm project is to create a mobile, affordable, responsive, and comfortable prosthetic arm that is capable of motor feedback. Alex, a first-year Biomedical Engineer, presented this project as a proposal to the Consumer Product Manufacturing (CPM) enterprise, and CPM excitedly agreed to initiate the project in the Spring 2025 semester. This project is currently in the research and feasibility phase, focusing on completing an extensive literary review and developing a model prosthetic to build off of.