216. Mechanical Properties and Microstructure of Gray Iron with Boron Contamination and Removal by Soda Ash

In gray iron, boron is an undesired contaminant that has adverse effects on mechanical properties. Soda ash has been shown to effectively reduce boron levels when added to molten gray iron. Further study was needed to understand the effects soda ash has on microstructure and mechanical properties. The goal of this project is to understand and quantify those effects. From cast samples, both with and without soda ash addition, tensile testing and hardness data were collected. Microstructural effects were analyzed as a function of cooling rate using modular step block castings.

217. Microstructural and Mechanical Effects of Reducing Hafnium in MAR-M247

MAR-M247 is a nickel-based superalloy, which is used in high-temperature applications such as gas turbine engines. Hafnium is used in MAR-M247 as it forms stable high temperature carbides that are useful in retaining strength in these high-temperature environments. However, hafnium has drastically increased in cost over the last few years and has a tendency to cause cracking during pour solidification. Howmet Aerospace, which produces components made of MAR-M247, is interested in reducing the weight percent of hafnium. Using simulation software, compositions of varying hafnium levels have been cast into test bars. These will then be assessed via microstructural analysis and mechanical testing to verify that the mechanical and casting properties are maintained or improved.

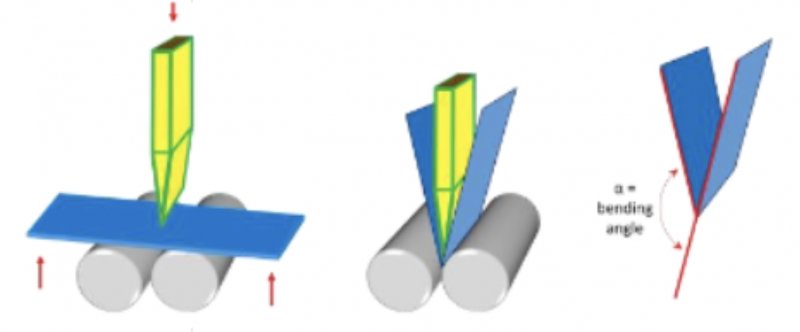

222. Optimizing Aluminum Extrusion Texture for Improved Bendability

The goal of the aluminum extrusion texture optimization project is to investigate ways to increase the cubic texture of 6005A aluminum and to study its correlation to bendability and energy absorption. The purpose of this project is to increase the safety to both the battery and passengers of electric vehicles in side impact collisions. This project is currently investigating the effect of homogenization treatment and the effect of composition on texture and bendability.

223. Optimizing Performance and Cost of Rail Grindstones

The grindstone project aims to develop a mixture and processing strategy to produce abrasive cutting materials for the rail grinding industry. The main purpose of this product is for the preventative maintenance of railroads, increasing their lifetime and reducing unnecessary outages. This project is currently in its mixture development phase as the processing for the production of the material has been largely completed. In the current phase, the team is developing a composition for the stones to optimize both grinding performance and cost.

228. Reducing Manganese Content in Solid Steel Weld Wire

The goal of the Hobart senior design project is to reduce the manganese content in solid steel welding wire to conform to OSHA requirements while maintaining mechanical properties of the wire. During the welding process manganese fumes are produced from the heat and these fumes can cause brain damage. Five steel compositions have been cast and are now in the manufacturing stage of the project, which includes rod rolling and wire drawing.