Manufacture part geometries no other process can.

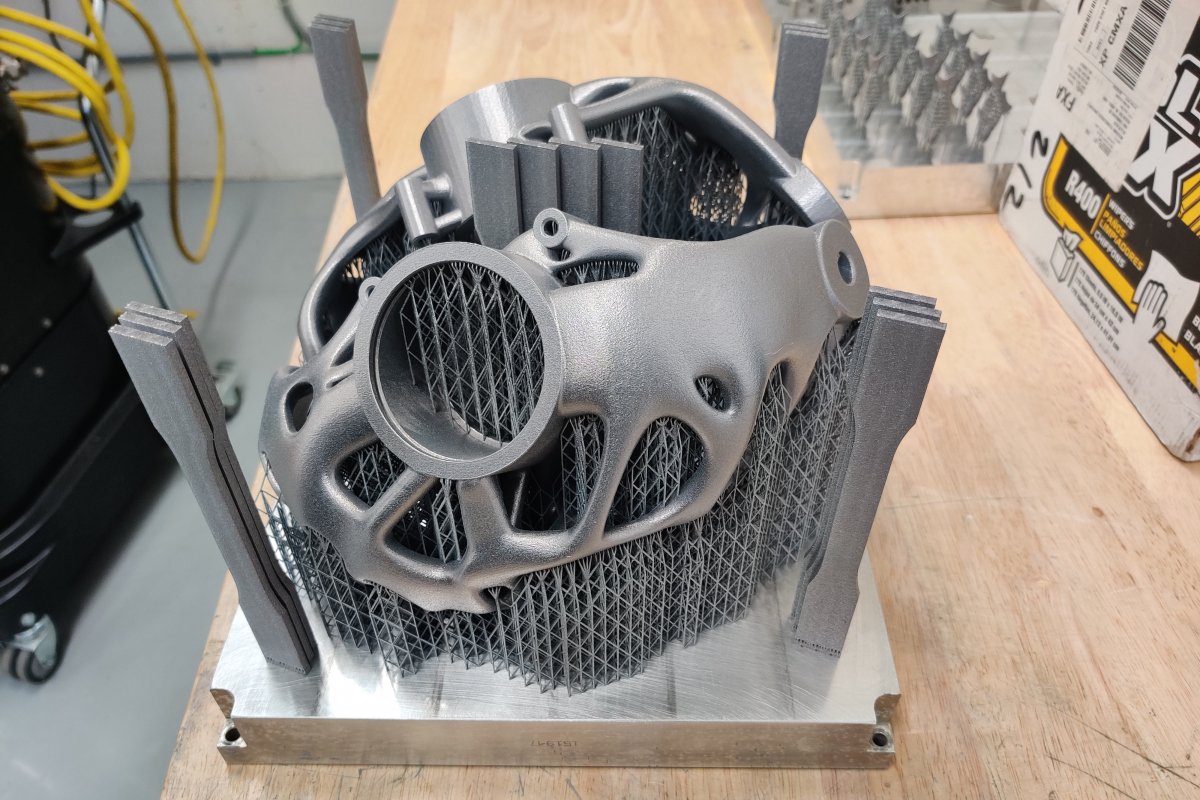

The Advanced Metal 3D Printing Center houses a powder bed fusion 3D Systems DMP Flex 350 Metal Printer. It is capable of producing parts with complex geometry from metal powders on a scale similar to industry standard. The printer can produce batches of parts on a daily basis.

Materials

- The printer is able to process 11 unique metals, including bio-grade titanium (for biomedical applications), cobalt and chromium, several types of steel, and more.

- We can use our own metal powders (custom powder alloys).

- It is possible to deposit experimental metal compositions in order to produce unique metal alloys customized specifically for the 3D printing process.

See Use Rates for standard materials. Check the materials calendar for current print focus.

Specifications

The printer is about 9 feet tall and weighs 10,000 pounds.

- DMP: Direct metal printing, a type of additive manufacturing

- Resolution: 5 microns

- Part Size: Approximately a 1-ft. cube size billet with maximum part size 275 x 275 x 420 mm (10.82 x 10.82 x 16.54 in).

- Print Specs: Minimum Z layer thickness is 5 microns with typical values of 30, 60, or 90. Repeatability in the XY and Z direction is 60 microns (0.002 inches). Minimum feature size is 200 microns.

- Purist Prints: The printing process offers extremely low oxygen levels (less than 25 parts per million), providing exceptionally strong, fully dense parts of high chemical purity.

Create one-off or unique parts, ideal for experimentation and testing of end-stage prototypes.

Knuckles printed in aluminum for the Blizzard Baja Enterprise team.