Many materials science and engineering (MSE) students feel both excitement and overwhelm at the prospect of applying their classroom knowledge to a capstone senior design project. Here’s how students at Michigan Tech meet the challenge — and win.

In 2022, students from Michigan Technological University’s Senior Design program earned first place in the national ASM International Undergraduate Design Competition for the fifth year in a row. The 2022 "five-peat" team designed a process for modeling the extrusion of aluminum-magnesium alloys with cerium additions that can maintain their strength at service temperatures up to 400 degrees Fahrenheit.

As the deadline approaches for the design team’s 2023 entry, team advisor Paul Sanders, Michigan Tech’s Patrick Horvath Professor of Materials Science and Engineering, shares the process of leveling up the Senior Design program. In this Unscripted guest blog, Sanders explains why he got involved — and how the efforts of industry, faculty and alumni continue to activate hands-on learning with proven methods that yield real-world results.

MSE Program Improves Senior Design Project Outcomes

First, our recipe for success includes Michigan Tech undergraduate students with an application mindset, hands-on problem-solving skills, and openness to mentorship. Next, it includes our methodology and the support of alumni and industry sponsors. Last but not least, it includes a faculty member willing to implement the vision. That would be me, a then-assistant-professor who was (somewhat unknowingly) selected for the endeavor in 2010. MTU Professor Mark Plichta, an innovator in project-based engineering education, and Northwestern University Professor Greg Olson, a leader in the relatively new field of computational materials engineering, asked me to take it on. Plichta and Olson tasked me to leverage my Michigan Tech BS, Northwestern PhD, and materials design experience at Ford Motor Company in implementing their vision, which included using computational materials engineering — a tool that, at the time, was only taught in graduate school.

Through a sometimes bumpy continuous improvement process, we developed the current MSE curriculum at Tech. Our strategy was to introduce students to traditional hypothesis-based inquiry through application of engineering statistics, coupled with design of experiments (DOEs) in both the modeling and laboratory environment. Eventually a methods course was developed for juniors that included a semester-long project to demonstrate the tools, followed by two semesters of the capstone Senior Design course. I led this coursework and scoped projects to fit the Michigan Tech methodology. Long-term industry sponsors Eck Industries, ArcelorMittal and Waupaca Foundry were critical to making the vision a reality, providing industry-relevant projects that allowed students to use the toolset taught in the curriculum.

"Michigan Tech undergrads, with their application mindset, hands-on problem-solving skills, and openness to mentorship, provided the ideal culture for this endeavor."

Olson provided the computational engineering software tool Thermo-Calc. One of his conditions was that Michigan Tech compete in the ASM Undergraduate Design Competition. The event got its start in 2008. Michigan Tech entered in 2012, earning second place behind Northwestern, who also won the very first competition. Over our first five years of competition, Tech earned second place three times and third place twice. And then, beginning in 2018, Michigan Tech started winning — and continued winning for five years in a row. This is a credit to the students’ work on their projects and also to the methodology, along with the support of industry sponsors.

The Latest Winning MSE Design Project

The 2022 team that brought our total first-place wins to five was unique in that there was only one MSE student on the team: Isabella Wakeham Jaszczak. There were three mechanical engineering students: Nick Hopp, Jake Klotz and Jacob Longstreth.

Their winning project focused on cerium, the most abundant (and lowest cost) rare earth element, which is known to improve the properties of aluminum. Rare earth elements are often mined together. Because there is a higher demand for heavier rare earths, there is an excess of cerium. Project sponsor David Weiss, vice president of research and development at Eck Industries, collaborates with research teams that identify beneficial uses and markets for cerium in order to improve the economics of mining rare earths. Weiss suggested applying cerium to aluminum extrusion for Eck’s customer, Eaton Corporation.

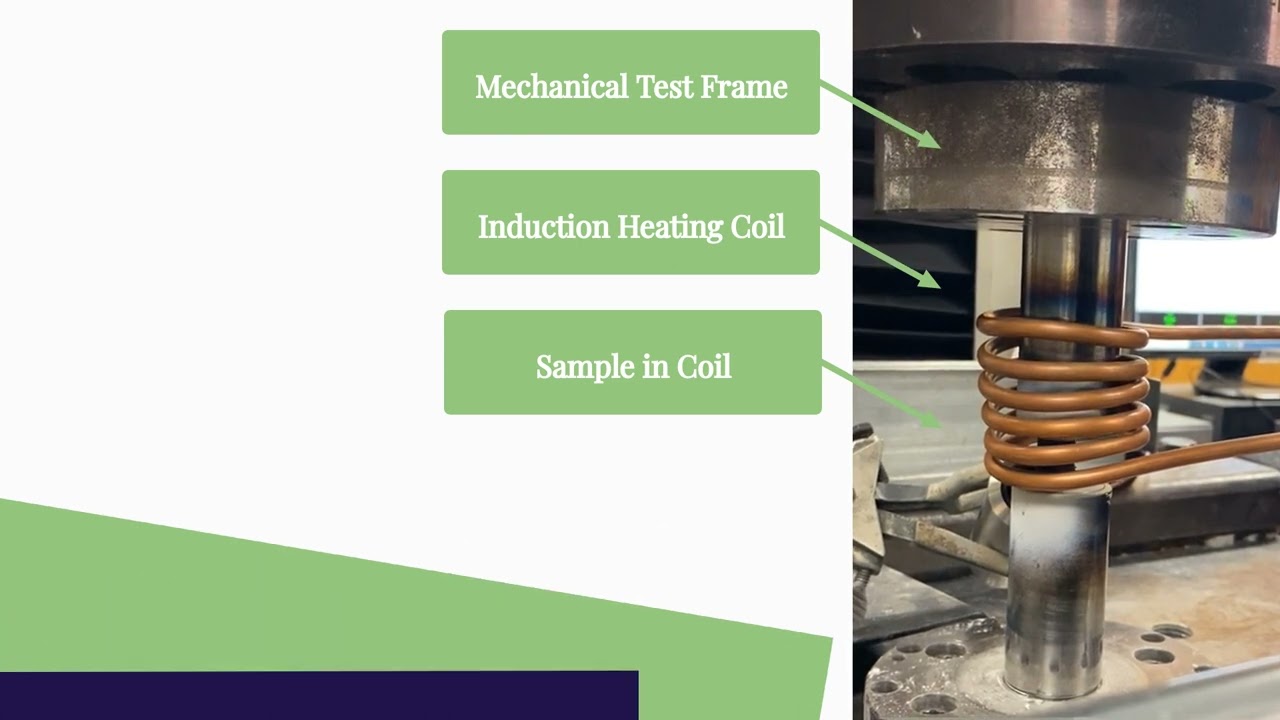

Extrusion is the process of forming long, two-dimensional cross-sections by forcing hot metal through a die. The students were tasked with modeling the extrusion of aluminum-magnesium-cerium (Al-Mg-Ce) alloys to predict the necessary extrusion force and resultant flow rate. The team used a DOE-based strategy to develop a deformation model for the alloy using elevated-temperature compression testing coupled with MATLAB data analysis. Material model parameters were then entered into the commercial extrusion modeling software Inspire Extrude from Altair to calculate the extrusion force and flow rate. These predictions were tested in Michigan Tech laboratories by permanent mold casting the custom Al-Mg-Ce alloys followed by extrusion on a 550-ton Breda direct extrusion press donated by Alcoa.

Watch a video detailing the 2022 team project.

Even though the students graduated in spring 2022, I was pleased that three out of four team members were able to be in New Orleans last September to accept their award at ASM International's IMAT Conference. These Huskies are a strong example of why I chose to return to Tech as an MSE faculty member. My decision was motivated in large part by the type of students Michigan Tech attracts. They are smart, hardworking and willing to learn. They embrace the time-consuming process of project engineering. And, they become loyal alumni who contribute to the success of the MSE Senior Design program by providing the projects that continuously improve our process.

Michigan Technological University is an R1 public research university founded in 1885 in Houghton, and is home to nearly 7,500 students from more than 60 countries around the world. Consistently ranked among the best universities in the country for return on investment, Michigan's flagship technological university offers more than 185 undergraduate and graduate degree programs in science and technology, engineering, computing, forestry, business, health professions, humanities, mathematics, social sciences, and the arts. The rural campus is situated just miles from Lake Superior in Michigan's Upper Peninsula, offering year-round opportunities for outdoor adventure.

Comments