NOTE: It is very important that you are focused and registered at this step.

1. Click Get Image. At Area x Zoom = 256 x 8, focus and register M1-200.

2. Use the SPUTTER TOOL to draw a rectangular box with the following parameters:

- Dimensions: ~11 x 2

- Time: At least 4 min. per edge

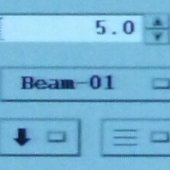

- Scan: see image below.

![]()

Repeat for the lower edge of the protective pad.

NOTE: Repeat the two preceding steps as necessary, alternating the mill on the upper and lower edge on the taper only, until specimen thickness measures 1 µm.

3. At Area x Zoom = 32 x 2, focus and register M1-100.

4. Repeat steps 2 -3 until the specimen is 0.6 µm.

5. Focus and register M1-50.

7. Focus and register M1-50 or M0-50.

8. Final milling:

8.1. Change to Area x Zoom = 32 x 1.

8.3. Enter 1 degrees to tilt.

8.4. Change area to Area x Zoom = 32 x 2 and Speed: 5. Use the SPUTTER TOOL to draw a rectangle with the following parameters:

- Dimensions: ~11 x 0.5

- Time: At least 4 min. per edge

- Scan: see image below (away from edge).

![]()

Correctly position the box on the upper edge.

8.5. Change Area x Zoom = 32 x 8 and press Fabrication Start. Run the mill many times to check the edge. Run until the specimen is ~70 nm.

NOTE: After changing the Area x Zoom to 32 x 8, only adjust the box VERTICALLY.

8.6. Change to Area x Zoom = 32 x 1 and Speed: Rapid.

8.7. Under the Stage menu, enter -1 degrees to tilt.

8.8. Change area to Area x Zoom = 32 x 2 and Speed: 5. Use the SPUTTER TOOL to draw a rectangle with the following parameters:

- Dimensions: ~11 x 0.5

- Time: At least 4 min. per edge

- Scan: see image to the left (away from edge).

REMINDER: After changing the Area x Zoom to 32 x 8, only adjust the box VERTICALLY.

8.8.1. Change Area x Zoom to 32 x 8 and press Fabrication Start. Run the mill many times to check the edge. Run until the specimen is ~70 nm.

8.8.2. Change Area x Zoom to 32 x 1 and Speed: Rapid. Under the Stage menu, enter 0 degrees to tilt back.

8.8.3. Change Area x Zoom to 32 x 8 and focus. You may need to change to Speed: 5. Click Get Image and measure.

8.8.4. The final specimen should be 50-70 nm.

9. Shut down the FIB after Lift Out. See Shut Down in Operating Procedures under Hitachi FB-2000 FIB.